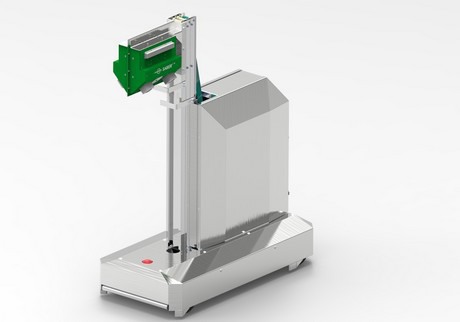

It looks like a lift cart, it works like a lift cart but it’s not just a lift cart. The new Ecoation machine, the OKO lift cart, not only enables workers to lower, clip or twist the plants, but at the same time collects a large amount of data, offering insights on the crop and the expected yield.

Multiple tasks

"In large greenhouses, you need multiple people to do multiple tasks", Saber Miresmailli with Ecoation explains. "The general crop work of course, but also scouting for pests, checking the crop, measuring climate details... Even with the help of different systems, still various people with various skills are needed to do all of this."

The newly designed machine enables you to do this at once. "The OKO lift cart is equipped with a lot of technology to collect data while working on the crop", Saber shows.

Yield prediction, climate conditions and IPM

The cart is equipped with a camera, assessing the yield (count and color of the fruits as well as flowers). Then there are the climate conditions, measured by various sensors. "When you change climate through out the day and season, you want to make sure all rows and posts grow under the same conditions. The system shows you variation in each posts."

The third activity is the pest and disease monitoring, allowing growers to record IPM observations through an interactive monitor and include the exact position of where the issue was observed. These records are registered in a digital platform where the IPM manager can assign tasks and remedies at early stages.

A very proud Saber in front of the OKO machine. Remarkable: “Some plants emit a kind of SOS chemical signal when they are in distress. We can use these signals to monitor their state of health,” he said a decade ago, when he was a student. Now the time is there and his horti-dream is realised.

SABER sensor

The SABER sensor, designed by Ecoation, plays an important role in the scouting of the pests and diseases. The sensor can detect and map plants' defensive signals. "When plants are under stress, they change their chemistry. Before they show visible signs of stress, one can tell that a plant is not happy by assessing these chemicals", Saber explains. "Our SABER sensor scans the plants and detect crop stress and IPM issues at early stages. In addition and thanks to the deep learning, it will only get better at doing so."

Trustworthiness

According to Saber, their new 3+1 lift cart not only saves time and increases the productivity of workers in the greenhouse, but also enlarges the trustworthiness of the measurements. "A machine measures constantly, is not affected by personal circumstances. And since the machine is easy to operate, an employee only needs basic training."

The information collected, allows growers to get a better insight on their crop. "You gather intelligence from every square meter of the greenhouse, making it possible to enlarge the consistency and crop health in every single post, in every single row. And the yield predictions offer valuable information to the sales department"

Finding and fixing problems

Saber explains how Ecoation's mission is to find and fix problems at an early stage. This also led to the creation of the IRIS! robot, which was launched earlier this year and uses the IPM monitoring SABER sensor as well. In fact, it also predicts yields and offers climate and environmental information.

Other than the OKO lift cart, the IRIS! vehicle can row shift on its own and cover the greenhouse without human help. "The IRIS! works autonomously", Saber confirms. "Our machines can talk to sprayer robots and we are now working on systems that can place biocontrol agents on the plants automatically or treat them with UVC light." The autonomous vehicle, a result of the collaboration with Metazet and Micothon, was launched at the GreenTech and won the Innovation Concept Award.

High-tech

It all sounds pretty high-tech - and to be honest this is the case. Since 2016, Ecoation has been supported by investors from NASA, Microsoft, Yahoo, Amazon and even the former Canadian Ambassador in China. Also within the horticultural industry, they have quite a network: collaborating with Metazet/Formflex, Micothon, Delphy and Biobest, working with prominent growers and having Casey Houweling from Houweling Tomatoes and Peter Quiring from Nature Fresh Farms on their advisory board.

"At Ecoation we build technology for growers by growers", Saber concludes. "I am convinced artificial intelligence and robotic platforms will play an important role in the future of horticulture and we can help growers putting this to work for them as well."

For more information:

Ecoation

www.ecoation.com

info@ecoation.com