The Sabatier Reaction is the process in which carbon dioxide is reacted with pure hydrogen to form methane and water. The reaction takes place at 300 – 400 oC in the presence of a catalyst (in this case, commonly aluminium oxide). Methane is the main component of natural gas, which powers most gas combined heat and power (CHP) engines in greenhouses throughout the UK. Going back to GSCE chemistry, it is more commonly seen as:

Electrolysis of water is the process that decomposes water into its constituents, oxygen and hydrogen. The reaction occurs when electricity is supplied through an anode and cathode (the positive and negative electrodes placed in the water).

International Space Station

There is only a handful functioning Sabatier process in the world. One is aboard the International Space Station (ISS), where it uses CO2 exhaled by astronauts to produce water (one half of the reaction). Another is operated in Augsburg, Germany, by ‘Exytron’ where they use the Sabatier process to supply heat and power to a block of apartments in a closed loop system, meaning all produced CO2 is recycled.

During times where growers generally do not require CO2 for growing their crops, possible future greenhouses with an installed Sabatier unit could recycle the unwanted CO2 to produce extra methane for their boilers or CHP engine to produce additional heat or electricity.

There are currently no available commercial Sabatier units for growers as this is quite an expensive process, however, it could decrease depending on the outcome of the Exytron installation and other future installations. In the future, it could be a matter of recycling the unwanted CO2 produced by a CHP engine or boiler and create more CH4 fuel, either to be used by the engines/boilers or injected to the grid, creating a closed loop system.

Testing the water

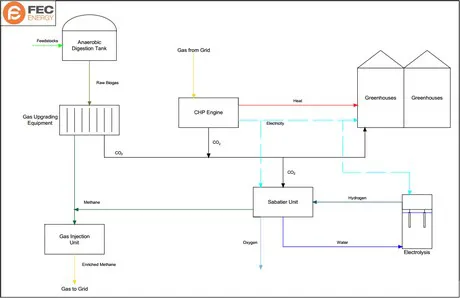

"The UK would be a great place for a system like this", Andrew believes. "Due to incentives like the Renewable Heat Incentive (RHI), and depending on its eligibility, placing a Sabatier unit within an AD plant could increase the amount of methane you inject to the grid and increasing your RHI income." The diagram below is a simple block diagram of how a Sabatier unit would work within an AD plant claiming RHI.

Click here to enlarge

From space to earth

"With astronomers, engineers, scientists and some politicians looking to become an interplanetary species, we are beginning to understand just how fortunate Earth is to have such a rich resource of energy that may not be available on other planets", Andrew says. "With Mars, for example, scientists are certain no fossil fuels will be found under the surface due to an absence of life and if we were to colonise Mars, other sources of energy will be required."

The use of PV solar panels is already used onboard spaceships, satellites and satellite telescopes as a source of power. Due to the advancement of PV technology for producing power in space, PV panels are becoming more readily available to the general public due to these improvements and decrease in manufacturing costs.

"Beyond this, in order to be able to survive outside of earth, humans will have to become increasingly efficient with the resources that they do have. Some of the proposals for energy use in space will no doubt help to improve efficiencies here on earth."

Commercial use for growers

Powering the Sabatier unit will be another hurdle to overcome. As the reaction requires a maximum of 400oC, heating up the CO2 via a heat transfer fluid would be the best practise as CO2 is nonflammable and much safer than heating up hydrogen. Heating the fluid to 400 oC could be done in a number of ways, either by the engine itself or from an onsite biogas or biomass boiler, but would require additional equipment, like heat exchangers and pumps.

There are a number of technologies that could be used to supply power, heat and reactants for the operation of the Sabatier unit, however, more research and development will be required before the Sabatier process can be commercially used for growers.

For more information:

FEC Energy

FEC Energy10th Street

Stoneleigh Park

Kenilworth

Warwickshire

CV8 2LS

024 7669 6512

info@fec-energy.co.uk

www.fec-energy.co.uk