If you are re-using thermoform, hard plastic, polyform or polystyrene trays; there is always a big chance that disease-bearing organic material is left behind on it. That is why more growers invest in tray washing units to wash the trays with high pressure hot or cold water in combination with a cleaning solution in the form of chemical liquids.

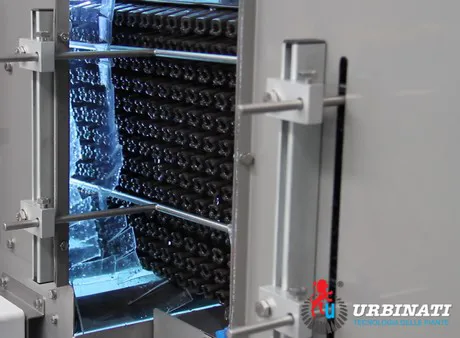

But what if you are growing organic crops? Then you are not in a position that you are allowed to use chemical cleaning agents? The Italian machine builder Urbinati has found a solution for this; disinfecting the trays with the Ultraviolet light of Cleanlight.

Disinfecting the trays with the Ultraviolet light of Cleanlight.

"After the trays are being washed with pure water with a pressure of 10 bar, they will get a second and final disinfection treatment in a tunnel with UV lamps", said Alessandro Mazzacano of Urbinati. "The UV light will kill all micro-organisms on the trays without harming the material of the tray. This is a very efficient treatment that is highly suitable for organic growers or growers that want to use less or no chemicals inside their operations."

According to Mazzacano the tray washers with UV treatments find great adaptation in Europe. "In North Europe many are regulated and there are strict controls on the products that are used inside the nurseries, growers want to work with sanitized materials at any time because they are aware of the risks of a pest outbreak. But nowadays this is also becoming the mentality in North and South America as well as Australia and new coming markets worldwide, also there, the rules are becoming stricter and the policy is almost the same as in Europe."

The tray washers of Urbinati can wash up to 500 standard sized trays per hour. The unit can be installed independently or integrated as part of the entire production line. Mazzacano: "It is suitable for any kind of grower, large or small scale because it can be electronically adjusted to the preferences of the client in terms of washing slowly for a more accurate cleaning or faster in order to guarantee higher speed production.

Urbinati can deliver the unit with automated tray de-stackers that can de-stack the 500 trays of full production, as well as with a final automatic collecting stacking unit to stack the washed trays again.