As Dave Van Belle gives us a brief overview of his company, he says that Van Belle Nursery is divided in two main growing divisions. "One of them is the YoungPlant

division", said Van Belle. "The YoungPlant division propagates mostly cold hardy shrubs, vines and starter plants. Those plants are shipped to growers all over Canada and the United States. We also have a "Retail Ready" division that takes care of 2-5-10 gallon pots with shrubs, perennials, vines, fruit & vegetables plants, hanging baskets and so on. Basically that is a one stop shop for the box stores in Western Canada. Our closest store is a 4 or 5 hour drive, and the furthest store is a two day drive. All of these products are packed and shipped according to the customers ' preference."

division", said Van Belle. "The YoungPlant division propagates mostly cold hardy shrubs, vines and starter plants. Those plants are shipped to growers all over Canada and the United States. We also have a "Retail Ready" division that takes care of 2-5-10 gallon pots with shrubs, perennials, vines, fruit & vegetables plants, hanging baskets and so on. Basically that is a one stop shop for the box stores in Western Canada. Our closest store is a 4 or 5 hour drive, and the furthest store is a two day drive. All of these products are packed and shipped according to the customers ' preference."

For the propagation of the young plants, Van Belle uses modern facilities. "We have a rolling table system from Logiqs Agro", said Van Belle. This is a 10 acre outside rail-yard and 3 acres of tables are inside a greenhouse. All the benches be can rolled outside to put the plants on the ground. We have adapted multiple techniques inside and outside the greenhouse to optimize the operations, such as an automatic pruner and a spraying boom for fertilizers and herbicides. Our philosophy is also to touch the plants as little as possible. Once a plant is propagated, we do not want to touch it any more, until it is shipped. In this order, we are able to optimize our operations, and make them less labor-intensive."

Labor is one thing Van Belle notes as a big expense in an intensive nursery operation. "We work with experienced seasonal workers from Mexico that are driven, and ambitious about learning things", said Van Belle. Every year Van Belle flies to Canada as part of the guest worker program. Van Belle also has many experienced, dedicated permanent staff and together this strong team of employees are one of the reasons they survive in a market that gets harder every year.

"The future of small nurseries in Canada is uncertain, noted Van Belle Nursery's President. He thinks that the business doesn't offer small operations enough money to survive, so only the large nurseries will be able to stick around. As a medium-sized company, Van Belle knows that they have to be special in order to continue as a business, and that an emphasis on flexibility will be the thing that keeps them in the game.

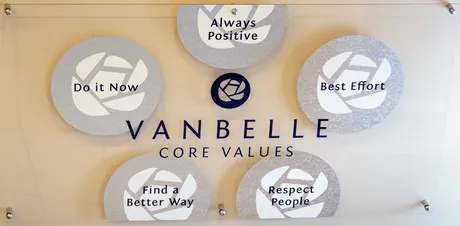

“Our company culture is all about being flexible and changing,” said Van Belle. A large part of that flexibility is due to their logistics innovations that rely heavily on computer programs that make things run smoothly.

“Every picker has a computer tablet that tells him what to pick, and when they drop off things at the receiving dock, someone there checks them in with another tablet,” explained Van Belle. All aspects of the operation, to the largest extent possible, are handled via computer, so much so that Van Belle expects to go paperless within the next year. He noted that, while relying so much on computers to automate things makes everything easier, it wouldn't have been possible without first being open to such an approach.

“We have three computer programmers on our staff who wrote all of the programs that manage our operation,” said Van Belle. That gives them a big edge among nurseries because it makes things easier to track and it makes them flexible in an industry where the ability to adapt from day to day is key. He cited their ability to print their own tags on the same day their plants are shipped to retail stores as an example of their flexibility, and he added that they're always looking for new innovations, whether it be from a logistics standpoint or trying to find new beneficial microorganisms to use in their growing soil. The main thing is that the business is constantly changing, and they have to change with it.

“We don't know what we're going to ship from day to day, and that makes things challenging,” said Van Belle. “It's very difficult, but it also distinguishes us from the competition.” Automation is also a big driver of their success, with the goal being not to have to touch the plants from when they are put in the ground until they are shipped. All work, from irrigation to spraying, is done with the help of machines on their 80 acre facility, and that's allowed Van Belle Nursery to increase their business while their overall workforce has remained lean. Being able to adapt has served them well, and Van Belle thinks that it's the only way they can survive.

“So far, we've been very flexible because of our computer systems and our culture,” he said. “And that's helped us to survive.”

For more information:

For more information:Van Belle Nursery

Dave Van Belle

www.vanbelle.com

T:1-888-826-2355

F: 604-853-6282

facebook.com/vanbellenursery

twitter.com/vanbellenursery